Release time:July 22, 2025

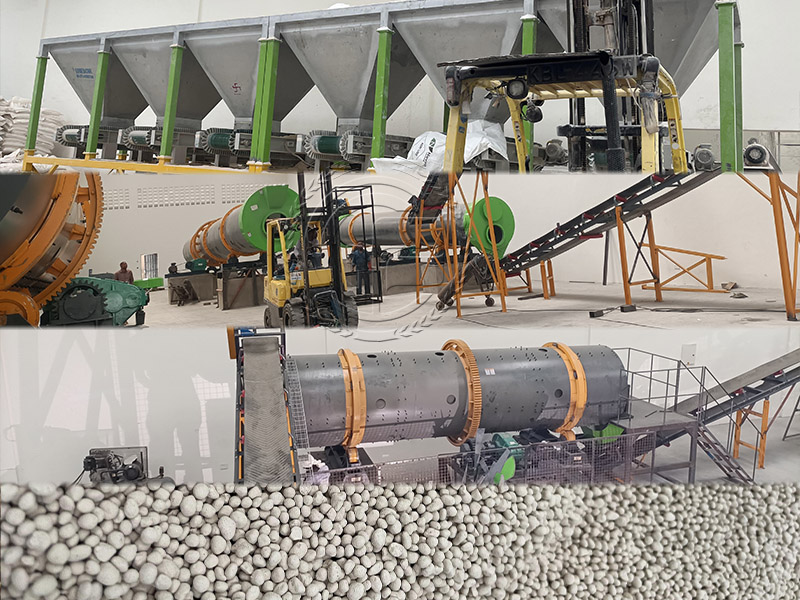

NPK fertilizer has become the mainstream fertilizer in modern agriculture due to its balanced nutrients and wide range of applications. Our NPK fertilizer granulation production line, with full-process collaborative operation and precise granulation technology, converts raw materials such as nitrogen, phosphorus, and potassium into NPK compound fertilizers with uniform particles and stable nutrients, providing fertilizer companies with efficient production solutions.

The production line controls quality from the pretreatment of raw materials. The raw material crusher can crush single-element fertilizers such as urea and monoammonium phosphate to 80-100 mesh to ensure uniform raw material particle size; the double-axis gravity-free mixer uses a special paddle design to achieve full mixing of materials within 3-5 minutes, with a mixing uniformity of ≥98%, providing uniform raw materials for subsequent granulation to avoid particle nutrient deviation caused by uneven mixing.

The core granulation link determines the product form and quality. Adopting roller extrusion granulation or disc granulation technology, the roller extrusion granulator uses high pressure molding, does not require too much adhesive, the granule strength reaches 8-12N, the molding rate exceeds 95%, and the granule shape is regular; the disc granulator uses the rotating centrifugal force and spraying system to produce round and smooth granules. Both methods can flexibly adjust the particle size (2-6mm) to meet the needs of different crops and fertilization methods.

Intelligent collaborative operation improves production efficiency. The production line is equipped with a PLC intelligent control system, which can adjust the granulation speed, pressure and other parameters in real time to ensure stable granulation effect. From granulation to drying, cooling, and screening, each link operates in linkage, and 3-15 tons of NPK fertilizer can be produced per hour. The screening equipment will screen the unqualified particles and return them for reprocessing, and the raw material utilization rate reaches 99%, which greatly improves production efficiency.

Environmentally friendly and energy-saving design reduces operating costs. The fully enclosed production structure is equipped with a negative pressure dust removal device, and the dust emission is ≤10mg/m³, which improves the working environment. The waste heat recovery technology is used in the drying process, which increases the heat utilization rate by 40% and reduces energy consumption by 30%. The key components are made of wear-resistant and corrosion-resistant materials, and the service life is extended to 8-10 years, which reduces maintenance costs and reduces the overall operating costs by 25%.

After a fertilizer company introduced this production line, the annual output of NPK fertilizer increased from 8,000 tons to 50,000 tons. The product successfully opened up the international market due to its uniform particles and stable fertilizer effect; after a fertilizer plant in Australia used it, the energy consumption in the granulation process was reduced by 35%, and the NPK fertilizer produced was well received at the local agricultural exhibition.

We provide customized production line design, multilingual operation training and global after-sales support. Choose the NPK fertilizer granulation production line to make NPK fertilizer production more efficient and high-quality! Contact us for exclusive solutions.

Hi, this is YAN, Want details & price?

Hi, this is YAN, Want details & price?