Release time:December 15, 2025

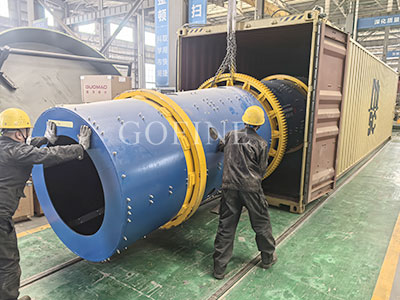

Yesterday, our meticulously crafted 3-ton-per-hour compound fertilizer production line for a Tanzanian client was successfully loaded into seven containers and officially set sail. This marks not merely a shipment of goods, but the departure of a comprehensive solution and renewed confidence in increased production—signifying a solid stride forward for the client in local fertilizer manufacturing.

Customized Design, Precisely Tailored to Needs

This production line was entirely customized based on the raw material characteristics provided by the client and local cultivation requirements. Core equipment—including the high-efficiency twin-shaft mixer, powerful granulator, multi-layer rotary drying and cooling system, and automated screening and packaging line—underwent precise calculations and selection to ensure seamless, efficient operation from feedstock input to finished product packaging. Its benchmark “3 tons per hour” design guarantees a favorable return on investment while leaving ample room for future market expansion.

Core Advantages: Stability, Efficiency, Intelligence

Constructed with proven processes and durable materials, the production line features core components with superior corrosion and wear resistance, adapting to the demanding conditions of compound fertilizer production for long-term, continuous, and stable operation. The integrated central control system significantly simplifies operation, enabling one-button start/stop and precise control of critical parameters to ensure consistent product quality metrics such as granule strength and nutrient uniformity.

End-to-End Service, Building Success Together

We provide comprehensive technical support throughout the entire process—from preliminary project discussions and solution design, to manufacturing, factory pre-installation and commissioning, and now packaging and shipment. Next, our engineering team will travel to the site to oversee installation guidance and production commissioning, ensuring the production line rapidly achieves target output. We also offer long-term operational maintenance and spare parts support, serving as a trusted, enduring partner for our clients.

These seven containers carry not only equipment but also our confidence in the quality of “China Intelligent Manufacturing” and our deep commitment to advancing global agricultural modernization. We look forward to this production line operating smoothly on Tanzanian soil, contributing to enhancing local fertilizer self-sufficiency and promoting agricultural abundance.

Hi, this is YAN, Want details & price?

Hi, this is YAN, Want details & price?