Release time:July 16, 2025

In the industrial production of compound fertiliser, granulation is the core of product quality and market competitiveness. The compound fertilizer granulation production line we launched, with professional granulation process and the whole process of coordinated operation, the nitrogen, phosphorus, potassium and other raw materials into uniform particles, strength qualified compound fertilizer, to provide efficient production solutions for fertilizer enterprises. Precise pre-treatment lays the foundation for granulation. The front end of the production line is equipped with raw material crushing and mixing equipment, which can crush urea, monoammonium phosphate and other monomaterial fertilisers to 80-100 mesh to ensure the uniformity of raw material particle size. The double-axis non-gravity mixer, through special paddle design, fully mixes the materials in 3-5 minutes, with mixing uniformity ≥ 98%, providing uniform texture raw materials for subsequent granulation and avoiding deviation of nutrients in particles caused by uneven mixing.

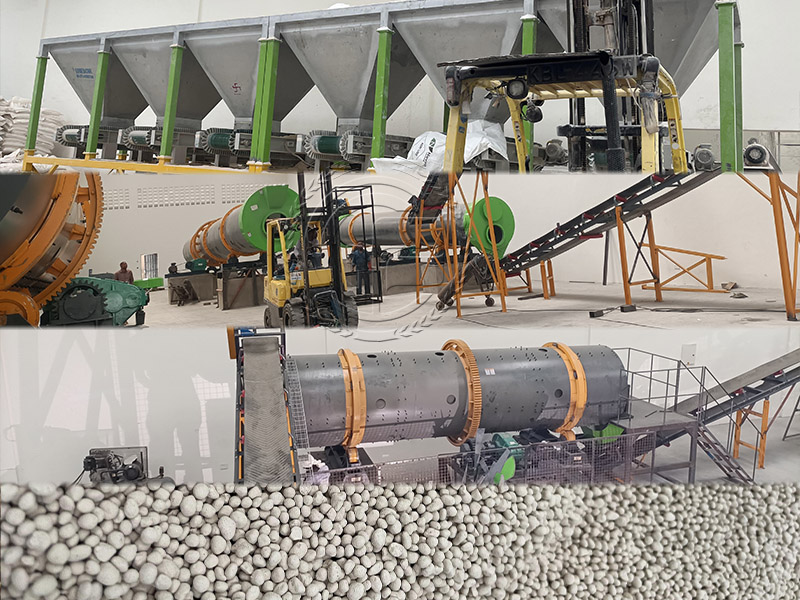

High-efficiency granulation to ensure product quality. The core granulation link adopts roller extrusion granulation or disc granulation technology. Roller extrusion pelletising machine adopts high-pressure moulding without adding too much binder, with pellet strength of 8-12N, moulding rate of more than 95%, and regular shape of pellets; disc pelletising machine adopts rotating centrifugal force and slurry spraying system to produce rounded smooth pellets, with flexible adjustment of pellet size between 2-6mm. Both pelletising methods can adapt to different raw material characteristics and meet diversified product requirements.

Intelligent co-operation, improve production efficiency. The production line is equipped with PLC intelligent control system, which can adjust the granulation speed, pressure and other key parameters in real time to ensure stable granulation effect. From granulation to drying, cooling and sieving, the equipment in each link operates in a linkage, and can produce 3-15 tonnes of compound fertiliser per hour. The screening equipment can screen the unqualified particles and return them for re-processing, the utilisation rate of raw materials reaches 99%, which greatly improves the production efficiency.

environmental protection and energy saving, reducing operating costs. Totally enclosed production structure with negative pressure dust removal device, dust emission ≤ 10mg/m³, improve the operating environment; drying link adopts waste heat recovery technology, heat energy utilisation rate increased by 40%, energy consumption reduced by 30%. The key components adopt wear-resistant and corrosion-resistant materials, which extends the service life to 8-10 years, reduces the maintenance cost of equipment, and lowers the comprehensive operation cost by 25%.

Case witnesses the strength. After the introduction of the production line to a fertiliser plant in Shandong, the annual output of compound fertiliser was increased from 8,000 tonnes to 50,000 tonnes, and the products were exported to the African market due to the uniformity of the particles and the stable fertiliser effect; after the use of the production line by a fertiliser enterprise in Australia, the energy consumption in the granulation process was reduced by 35%, and the compound fertilisers produced were highly praised in the local agricultural exhibitions.

We provide customised production line design, multi-language operation training and global after-sales support. Choose the Compound Fertiliser Pelletizing Line to make compound fertiliser production more efficient and high-quality! Contact us for a customised solution

Hi, this is YAN, Want details & price?

Hi, this is YAN, Want details & price?