Release time:January 15, 2026

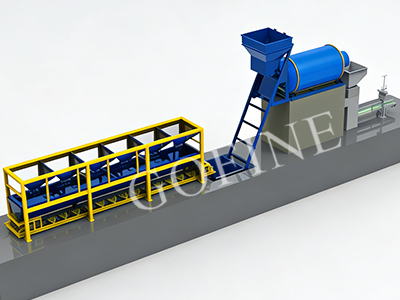

In today’s increasingly prevalent precision agriculture and soil-testing-based fertilization practices, blended fertilizers that can quickly respond to different soil and crop needs and flexibly adjust formulations have become a key product in modern agricultural services. Our intelligent, modular production line, specifically designed for blended fertilizer production, is helping fertilizer distributors, cooperatives, and processing plants worldwide transform basic raw materials into higher-value customized fertilizers, quickly capturing niche markets with its exceptional precision, efficient production flexibility, and stable and reliable quality.

Core Advantages: Precise Metering and Efficient Uniform Mixing

The core of this production line lies in its high-precision dynamic batching system and efficient twin-screw mixer. Using multi-bin separate metering, it can precisely proportion basic fertilizers such as granular urea, monoammonium phosphate, and potassium chloride, as well as micronutrients, with millimeter-level accuracy. The unique mixing design ensures highly uniform blending of materials in a short time, effectively preventing stratification caused by differences in particle physical characteristics, guaranteeing absolutely uniform nutrient distribution in every bag of finished product, and ensuring precise and reliable fertilization results.

Intelligent and Flexible, Multi-functional

The entire line uses PLC central control, allowing for one-click storage and retrieval of formulas, enabling rapid and seamless switching between “small batches and multiple formulas,” perfectly adapting to personalized custom orders. The modular design supports capacity expansion from 1 ton to 10 tons per hour, suitable for continuous operation in regional fertilizer blending centers and also ideal for providing on-site mobile fertilizer blending services for large farms, with extremely wide application scenarios.

Robust Quality, Long-lasting Stability

The main body of the equipment is made of high-quality carbon steel, with special anti-corrosion treatment on key contact parts. The core mixing components are made of high-strength wear-resistant materials, ensuring stable operation in long-term friction and corrosive environments with complex granular materials, resulting in low failure rates and a long service life.

Comprehensive Service, Worry-free Investment

We provide a full “turnkey” service, from process design, equipment layout, installation and commissioning to personnel training. Backed by our global after-sales network, we provide rapid spare parts supply and professional technical support, ensuring your production line becomes a reliable asset that continuously generates profits through a combination of remote monitoring and on-site maintenance. Choosing our blended fertilizer production line means not only acquiring a set of equipment, but also gaining a flexible production system and precise service capabilities that can respond to market changes at any time. It’s a wise choice for building a core competitive advantage in the highly competitive agricultural materials industry.

Hi, this is YAN, Want details & price?

Hi, this is YAN, Want details & price?